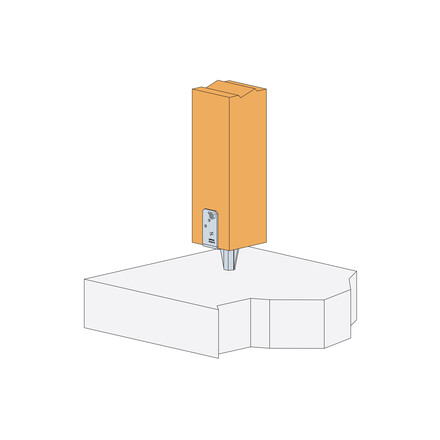

ZPRO Folded postbase

PBWS is single-piece, non-welded post base for connecting timber to concrete. An engineered soliution manufactured in Denmark, this connector requires less steel than a traditionally designed post base.

Tuotteen yksityiskohdat

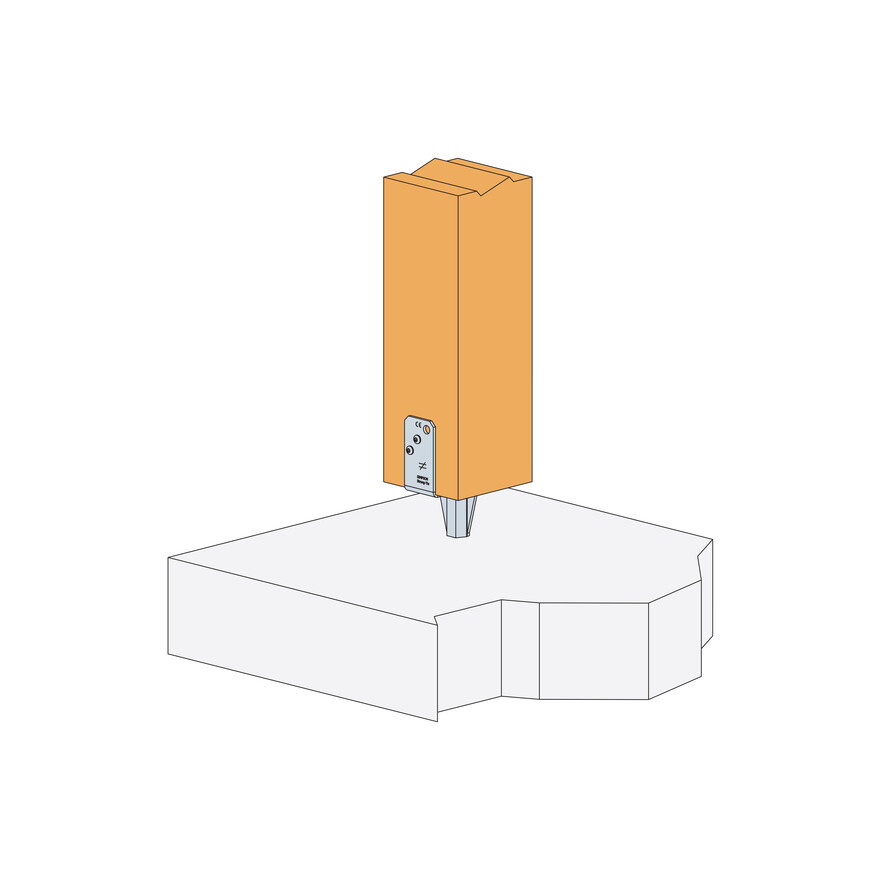

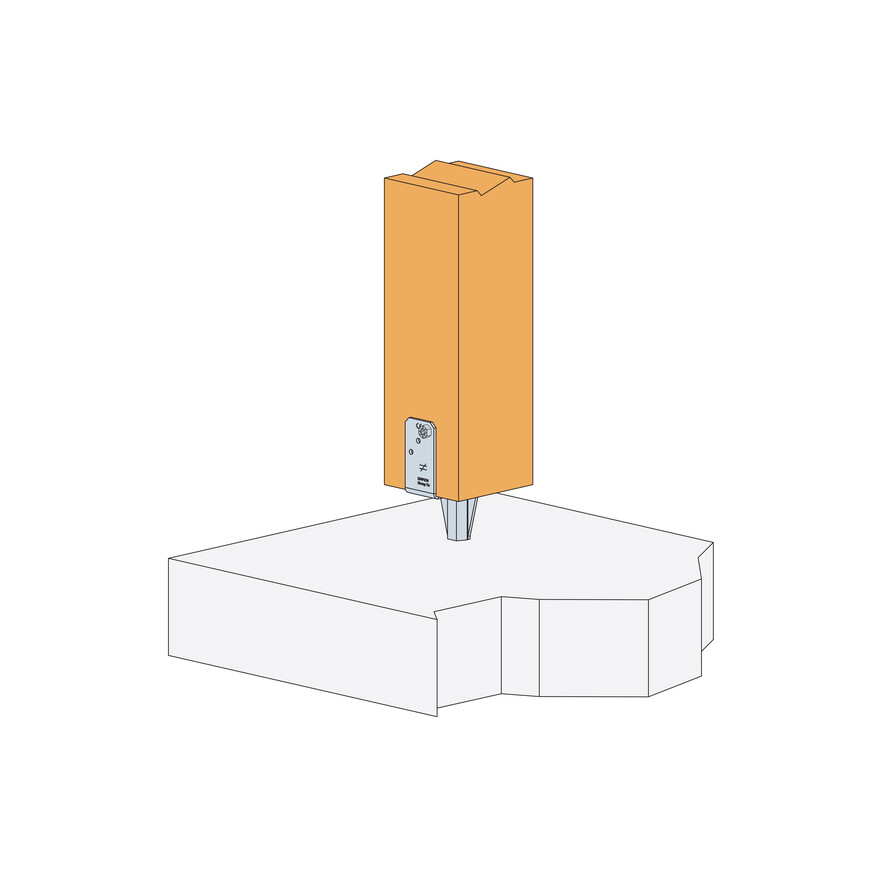

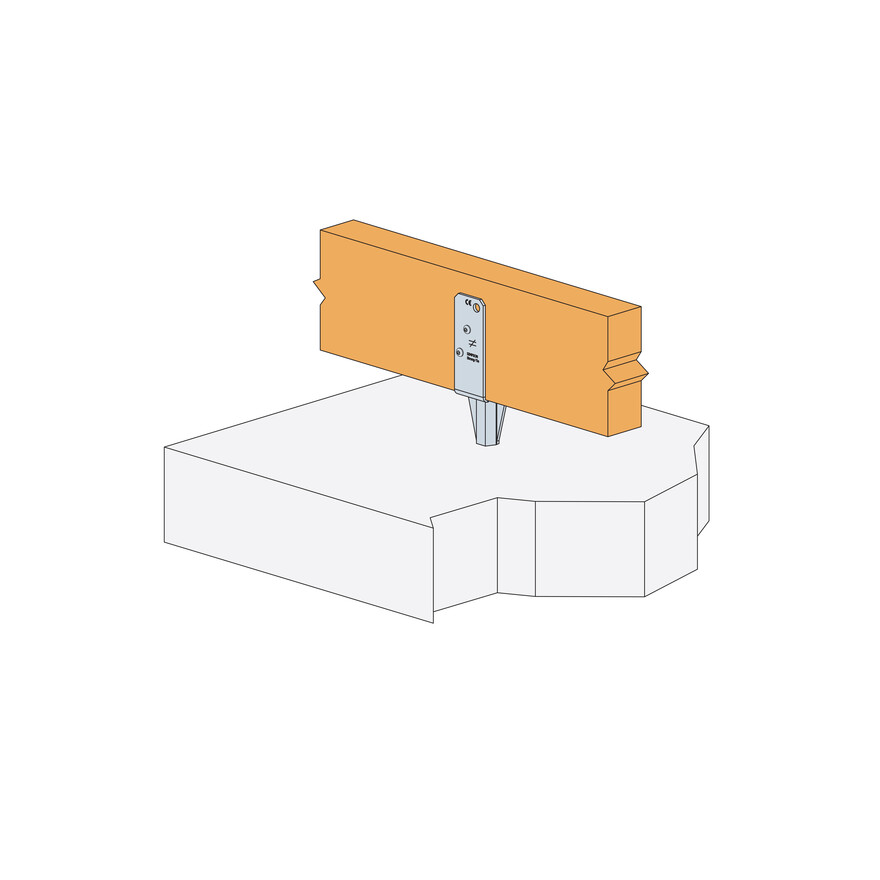

Kuvat

Ominaisuudet

Material

Steel:

S250GD + ZPRO

Corrosion protection:

ZPRO coating - corresponding to a zinc layer of approx. 55 μm

Benefits

- Light and easy to handle

- No pre-drilling required

- Reduced environmental impact due to material reduction

- Flexible fastening options

- Manufactured in Denmark

Features

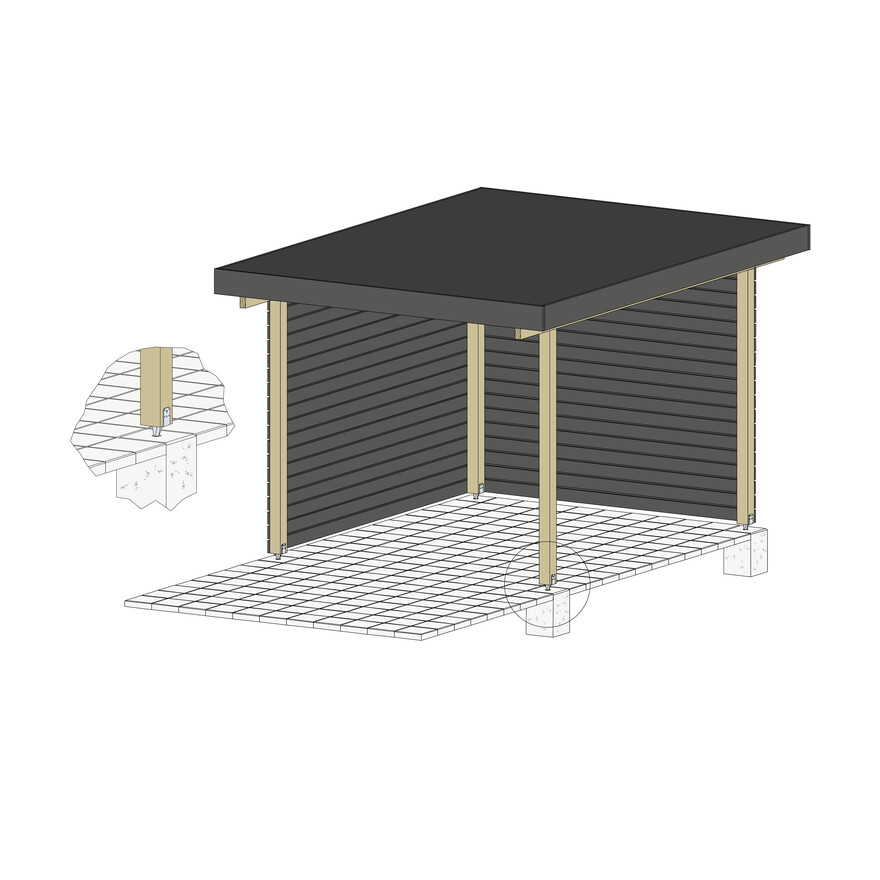

Built to last, the surface of the PBWS is protected using our ZPRO coating for improved resistance to corrosion compared with conventionally coated galvanised steel. This makes the PBWS a good choice for a wide variety of outdoor projects including pergolas, decking, car ports, fencing and sheds.

Optional hole patterns mean it can be fastened to the timber post using either 4 x CSA connector screws or 2 x SSH Hex Head screws, no pre-drilling is required.

Reduced Environmental Impact

PBWS offers the same load-rated capacity as standard post bases, yet due to it's unique folded build, requires up to half as much steel material to produce, making it better for the environment and easier to handle.

Extend the life of outdoor structures

Our innovative ZPRO coating provides additional corrosion resistance for structural steel connections typically used in outdoor settings such as car ports and gardens. It provides the same protection against the elements as a hot dip galvanised coating (corrosion category C3 EN ISO 12944) however ZPRO has a much neater, shinier finish.

Economical too, ZPRO bridges the gap between standard glavanised steel and the considerably more expensive stainless steel material.

Sovellus

Suitable on

- Supporting member : concrete,

- Supported member : solid timber, glulam...

When to use

- Pergolas

- Decking

- Fence posts

- Sheds

- Awnings

- Porches

- Car ports

Tekniset tiedot

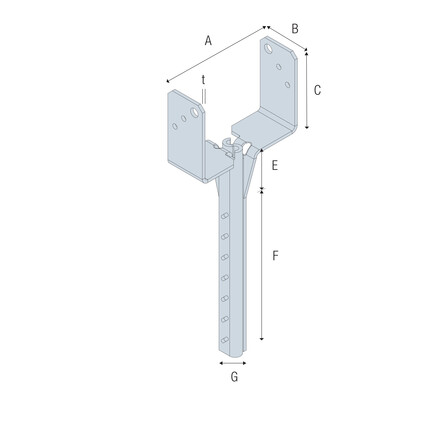

Product dimensions

| Tuotenro | DB nr. | NOBB nr. | Product dimensions [mm] | Top part holes | Box Quantity | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | E | F | G | t | Ø5 | Ø8,5 | ||||

| PBWS45Z | 2171209 | - | 45 | 40 | 99.5 | 50 | 150 | 22 | 3 | 4 | 2 | 20 |

| PBWS48Z | - | 57980924 | 48 | 40 | 98 | 50 | 150 | 22 | 3 | 4 | 2 | 20 |

| PBWS70Z | 2171210 | - | 70 | 40 | 87 | 50 | 150 | 22 | 3 | 4 | 2 | 20 |

| PBWS73Z | 2171211 | 57980958 | 73 | 40 | 85.5 | 50 | 150 | 22 | 3 | 4 | 2 | 20 |

| PBWS90Z | 2171212 | - | 90 | 40 | 77 | 50 | 150 | 22 | 3 | 4 | 2 | 20 |

| PBWS98Z | - | 57980962 | 98 | 40 | 73 | 50 | 150 | 22 | 3 | 4 | 2 | 20 |

| PBWS100Z | 2171194 | - | 100 | 40 | 72 | 50 | 150 | 22 | 3 | 4 | 2 | 20 |

Product capacities

| Tuotenro | Product capacities - Timber to Concrete | |||

|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 [kN] | |||

| On post | R1,k | R2,k | ||

| Qty | Type | |||

| PBWS45Z | 4 | CSA5,0x40Z | 20.2 | 2.5 |

| PBWS48Z | 4 | CSA5,0x40Z | 20.2 | 2.5 |

| PBWS70Z | 4 | CSA5,0x40Z | 20.2 | 2.5 |

| PBWS73Z | 4 | CSA5,0x40Z | 20.2 | 2.5 |

| PBWS90Z | 4 | CSA5,0x40Z | 20.2 | 2.5 |

| PBWS98Z | 4 | CSA5,0x40Z | 20.2 | 2.5 |

| PBWS100Z | 4 | CSA5,0x40Z | 20.2 | 2.5 |

*Minimum concrete strengt C12/15

Product capacities - Ø8 Connector screw

| Tuotenro | Product capacities - Timber to Concrete - Ø8 Connector screw | |||

|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 [kN] | |||

| On post | R1,k | R2,k | ||

| Qty | Type | |||

| PBWS45Z | 2 | SSH8x40 | 20.2 | 2.5 |

| PBWS48Z | 2 | SSH8x40 | 20.2 | 2.5 |

| PBWS70Z | 2 | SSH8x40 | 20.2 | 2.5 |

| PBWS73Z | 2 | SSH8x40 | 20.2 | 2.5 |

| PBWS90Z | 2 | SSH8x40 | 20.2 | 2.5 |

| PBWS98Z | 2 | SSH8x40 | 20.2 | 2.5 |

| PBWS100Z | 2 | SSH8x40 | 20.2 | 2.5 |

*Minimum concrete strengt C12/15

Asennus

Asennus

Fixing

On timber :

- CNA4.0 ring shank nails,

- CSA5.0 screws,

- Ø8 mm SSH screws,

- Bolts Ø8 mm.

On concrete :

- Chemical resin AT-HP

The distance between the plate and the concrete must be 50 mm maximum.

Installation

Upper part :

Place the post in the postbase,

Secure the post base to the post.

Lower part :

Secure the post base to the post,

Drill the support vertically, to the recommended diameter and depth,

Position the post and finalize the fixing to the ground using sealing,

The column base can also be embedded in the concrete when the latter is poured.